Why are speed sensor magnets installed on the side cover of a hub motor? What is the difference between one speed sensor magnet and six speed sensor magnets?

I. What is a hub motor speed sensor magnet?

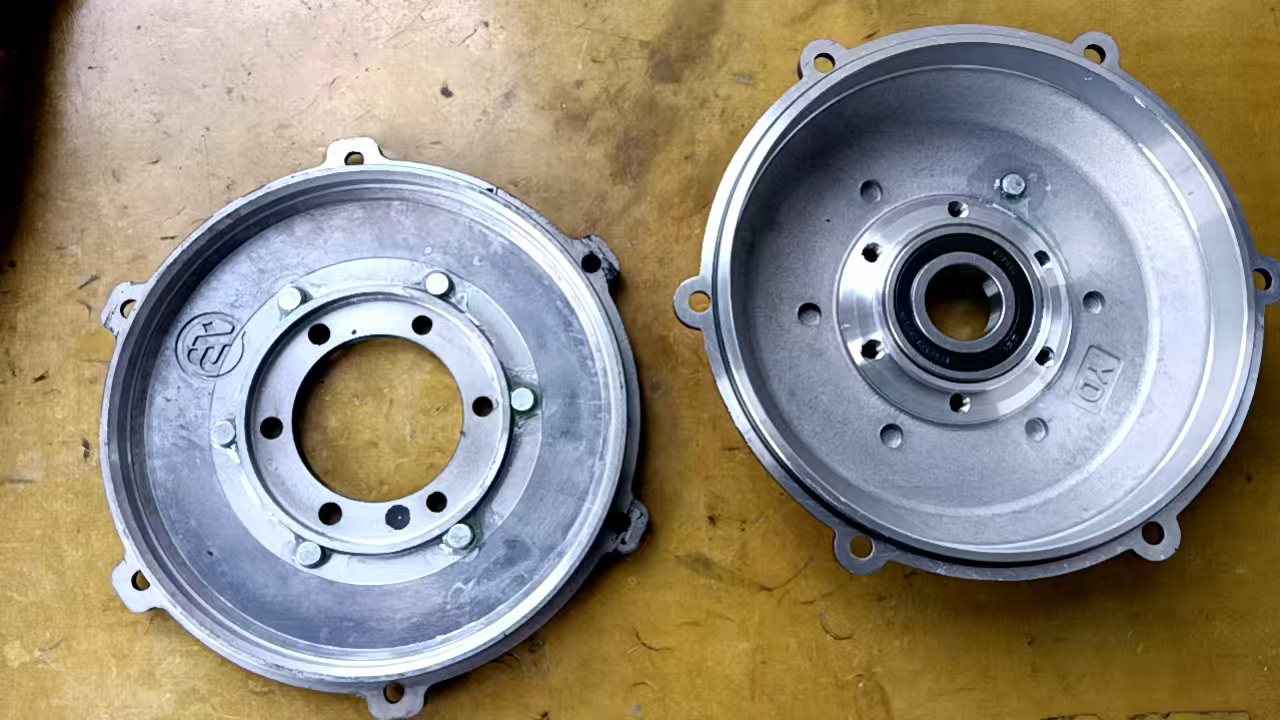

The speed sensor magnet is typically installed on the inner side of the hub motor’s end cover and works in conjunction with the **Hall speed sensor** in the controller.

Its core function is simple: to provide the controller with motor speed signals.

When the hub motor rotates, the speed sensor magnet passes by the Hall sensor, generating a pulse signal. The controller calculates the following based on the number of pulses per unit of time:

Real-time motor speed (RPM)

Vehicle speed (km/h)

Mileage accumulation

Pedal Assist System (PAS) working logic

Without the speed sensor magnet, the controller will be unable to accurately determine the motor’s operating status.

II. Why is a speed sensor magnet necessary for hub motors?

1. To achieve accurate speed measurement and display

It is used for displaying real-time vehicle speed and accumulated mileage on the instrument panel, meeting regulatory requirements and user experience needs.

2. To ensure normal closed-loop control of the controller

In sine wave control and FOC control, speed feedback is essential for:

Smooth starting

Stable cruising

Efficient operation

3. To support the pedal-assist system (PAS) and speed limiting function

Especially in European standard electric assist bicycles (EPACs), the speed signal directly determines:

The 25 km/h speed limit judgment

The timing of power assist cut-off

III. Key Differences Between Single-Speed and Multi-Speed Magnets

* Single Speed Magnet

Working Principle: The Hall sensor outputs 1 pulse for every rotation of the motor.

Technical Characteristics: Simple structure, low cost, low signal frequency.

Advantages: Suitable for low-speed, low-cost systems, low demands on the controller, easy installation and maintenance.

Disadvantages: Lower signal resolution at low speeds, less precise response to speed changes, slightly insufficient for high-precision control.

Typical Applications: Economical electric bicycles, ordinary electric tricycles, basic DC or square wave control systems.

* Multi-Speed Magnets (6 Magnets)

Working Principle: The Hall sensor outputs 6 pulses for every rotation of the motor.

Technical Characteristics: Higher pulse frequency, more precise speed calculation, faster dynamic response.

Advantages: More precise low-speed control, smoother starting and acceleration, suitable for sine wave/FOC controllers, more conducive to energy saving and efficiency optimization.

Disadvantages: Slightly higher cost, higher compatibility requirements for the controller.

Typical Applications: Mid-to-high-end electric bicycles, European standard e-bikes, high-efficiency PMSM hub motors, and models requiring a high-quality riding experience.

CZJB Hub Motor Speed Sensor Magnet Solution

As a professional hub motor manufacturer, CZJB offers the following solutions based on customer needs:

Customizable speed sensor magnet solutions with 1, 3, or 6 magnets

Speed sensing parameters compatible with various controller protocols

OEM/ODM side cover structure design

European standard E-bike compliance support

Ensuring stable, accurate, and efficient operation of the motor in different markets and application scenarios.

FAQ:

A: The controller cannot accurately detect speed, causing unstable control, PAS malfunction, and incorrect speed display.

A: Some controllers allow parameter adjustment, but compatibility should be confirmed in advance.

Not necessarily. The optimal configuration depends on controller type, application, and cost requirements.