How Temperature Sensors Protect E-Bike Hub Motors from Overheating?

As e-bike performance continues to improve, hub motors are becoming more powerful, compact, and efficient. However, higher power density also brings a critical challenge: heat management. Without proper temperature control, excessive heat can seriously reduce motor lifespan and compromise riding safety.

This is why temperature sensors, especially NTC thermistors, play a vital role in modern e-bike hub motors. In this article, we explain how hub motor temperature sensors work, why they are essential, and how CZJB integrates reliable thermal protection solutions for global e-bike brands

Why Temperature Control Is Critical in E-Bike Hub Motors

During operation, an e-bike hub motor generates heat from copper losses, iron losses, and mechanical friction. Under high load conditions—such as hill climbing, heavy cargo, or continuous high-speed riding—motor temperature can rise rapidly.

If overheating is not controlled, it may cause:

Permanent magnet demagnetization

Insulation aging and winding damage

Reduced efficiency and torque output

Controller failure or unexpected shutdown

For e-bike manufacturers targeting Europe, the USA, and other mature markets, thermal protection is no longer optional. It is a key factor in reliability, warranty cost, and brand reputation.

What Is an E-Bike Hub Motor Temperature Sensor?

An e-bike hub motor temperature sensor is a device that monitors the internal motor temperature in real time and sends feedback to the controller.

The most commonly used sensor is an NTC thermistor.

NTC Thermistor Explained

NTC stands for Negative Temperature Coefficient. This means:

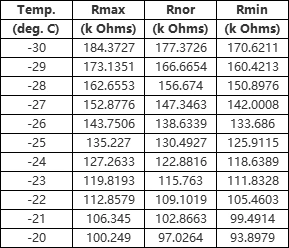

*As temperature increases → resistance decreases

*As temperature decreases → resistance increases

By measuring resistance changes, the controller can accurately calculate the motor’s internal temperature.

In most hub motors, the thermistor is embedded close to the stator windings, where heat accumulates fastest. This allows for fast and accurate thermal response.

How the Temperature Sensor Works with the Motor Controller

The temperature protection process inside an e-bike hub motor system typically follows these steps:

1.The NTC thermistor continuously measures internal temperature

2.The signal is transmitted to the motor controller

3.When temperature reaches a preset threshold, the controller reacts

4.Power output is reduced or the motor is temporarily shut down

This intelligent interaction between the hub motor temperature sensor and the controller prevents thermal damage before it becomes critical.

Different controllers may apply different protection strategies, such as gradual current limiting or instant cutoff, depending on system design.

Benefits of Thermal Protection in Hub Motors

Integrating a reliable temperature sensor into an e-bike hub motor offers multiple advantages:

*Prevents overheating and motor burnout

*Protects permanent magnets and copper windings

*Extends motor service life

*Improves riding safety and system stability

*Reduces warranty and after-sales costs

*Helps meet EU and US quality standards

For OEM and ODM customers, thermal protection is an essential feature when developing competitive e-bike products.

CZJB Hub Motor Temperature Sensor Design

At CZJB, temperature control is an integral part of our hub motor design philosophy.

Our e-bike hub motors can be equipped with high-precision NTC thermistors, carefully positioned near the stator windings to ensure accurate temperature monitoring. The sensor signal is stable and compatible with most mainstream motor controllers on the market.

Key features of CZJB thermal protection design include:

*Fast thermal response for real-time protection

*Reliable signal transmission under vibration

*Stable performance during continuous high-load operation

*Proven durability through long-term testing

This ensures consistent motor performance even in demanding riding conditions.

Applications in Real-World Riding Conditions

Temperature sensors are especially important in scenarios such as:

*Long uphill riding

*High ambient temperature environments

*Heavy-load cargo e-bikes

*Continuous high-speed operation

In these conditions, thermal protection helps maintain consistent power output while preventing irreversible motor damage.

Choosing the Right Hub Motor with Thermal Protection

When selecting an e-bike hub motor, buyers should consider not only power and efficiency, but also:

Whether a temperature sensor is integrated

Sensor accuracy and response speed

Compatibility with the controller

Manufacturer’s testing and quality control

A well-designed thermal protection system reflects a manufacturer’s technical capability and long-term reliability focus.

Conclusion

Temperature sensors play a critical role in protecting e-bike hub motors from overheating and premature failure. By using high-quality NTC thermistors and intelligent controller interaction, modern hub motors can achieve higher performance without sacrificing durability.

With reliable temperature sensor integration and flexible OEM customization, CZJB provides safe, efficient, and long-lasting hub motor solutions for global e-bike brands.